Side Mounted Magnetic Level Indicator

Price 1500 - 200000 INR/ Number

Side Mounted Magnetic Level Indicator Specification

- Accuracy

- 10 mm

- Connection

- Flanged (ANSI, DIN, JIS) or threaded connections as required

- Pressure

- Up to 25 bar

- Function

- Visual indication and monitoring of liquid levels in tanks and vessels by means of a magnetic float system.

- Size

- Suitable for tank heights up to 5000 mm (customization available)

Side Mounted Magnetic Level Indicator Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Week

About Side Mounted Magnetic Level Indicator

Application & Area of Use

The Side Mounted Magnetic Level Indicator finds its place across diverse sectors such as chemical processing, oil & gas, water treatment, and pharmaceuticals. Designed for optimal usage in tanks and vessels requiring visual level indication, it excels in monitoring liquids under various operating conditions. Its versatility ensures smooth integration, whether for hazardous chemical tanks, storage vessels in pharmaceutical plants, or water reservoirs in treatment facilities, delivering robust, real-time measurement and superior process safety.

FOB Port, Packaging, and Export Destinations

Delivered promptly from stock-ready inventory at major Indian FOB ports, each Side Mounted Magnetic Level Indicator is shipped with secure, impact-resistant packaging. Transport services ensure immaculate condition upon arrival, whether it's a local delivery or export. With main export markets spanning the Middle East, Africa, Southeast Asia, and Europe, clients benefit from streamlined shipping and adaptable logistics suitable for both small-scale and bulk orders.

FAQ's of Side Mounted Magnetic Level Indicator:

Q: How does the Side Mounted Magnetic Level Indicator visually indicate liquid levels in tanks?

A: It uses a magnetic float system coupled with bi-color rollers, flaps, or magnetic followers inside a glass chamber. As the liquid level changes, the float moves, triggering magnetic elements to provide vivid, immediate visual indication along the graduated scale.Q: What materials are offered for construction and float options to suit process requirements?

A: The indicator can be built from Stainless Steel 304, Stainless Steel 316, PP, or PTFE-lined materials. Float choices include stainless steel, titanium, or process-resilient plastics, ensuring compatibility with specific chemicals, temperatures, and pressures.Q: Where is the Side Mounted Magnetic Level Indicator typically installed?

A: It is side-mounted on industrial tanks or vessels, commonly found in environments such as chemical plants, oil & gas facilities, water treatment stations, and pharmaceutical industries where monitoring accuracy and reliability are paramount.Q: What benefits do the magnetic reed switches and transmitter compatibility provide?

A: Externally fitted magnetic reed switches allow for customizable alarms and digital signals. Compatibility with magnetic level transmitters supports continuous output for integration with control systems, boosting safety, automation, and process monitoring efficiency.Q: How precise is the level measurement and what are the connection options?

A: The indicator offers an accuracy of 10 mm, with scale graduations in mm, cm, or inches. Process connections are customized, available in flanged (ANSI, DIN, JIS) or threaded options, supporting pressures up to 25 bar.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Instrument Category

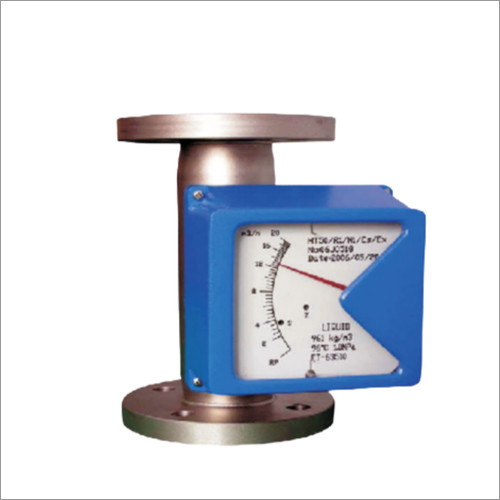

Metal Tube Magnetic Rotameter

Price 1500 - 200000 INR / Number

Minimum Order Quantity : 50

Size : 0 TO700

Accuracy : +20%F.S.D PSI

Function : FLOW MEASUREMENT

Connection : PROCESS CONNECTION

Side Mounted Magnetic Level Switch

Price 1500 - 200000 INR / Number

Minimum Order Quantity : 100

Size : Suitable for tanks with different heights and dimensions

Accuracy : 5 mm

Function : Liquid Level Sensing and Control

Connection : Flanged or Screwed (Customizable)

Flame Proof Reactor Vessel Lamp

Price 1500 - 200000 INR / Number

Minimum Order Quantity : 100

Size : Suitable for standard reactor vessel mounting, typically 150 mm to 300 mm diameter

Accuracy : Uniform lighting with high visibility for observation and operation

Function : Illumination of reactor vessels in hazardous or flameproof environments

Connection : Flanged or threaded mounting with cable gland entry

GST : 23AAJHV2265D1Z9

|

|

LINEX FLOWSENSE LTE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry