NRV Check Valve

Price 1500 - 200000 INR/ Number

NRV Check Valve Specification

- Usage

- WATER , ACID, OIL , CHEMICAL

- Sealing

- non

- Application

- WATER , ACID, OIL , CHEMICAL

- Voltage

- non Electromagnetic (emu)

- Structure

- Check

- Type

- WATER , ACID, OIL , CHEMICAL

- Power

- Manual

- Size

- 25NB to 150NB

- Pressure

- High Pressure

- Product Type

- check

- Color

- blue

- Disc

- SS316, SS 304, CI, CS ,WCB

- Pin

- 452001

NRV Check Valve Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- INDORE

- Supply Ability

- 100 Per Week

- Delivery Time

- 7 Week

- Sample Policy

- Contact us for information regarding our sample policy

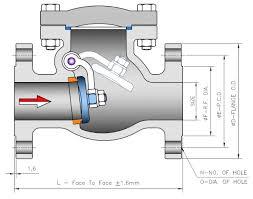

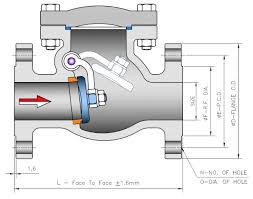

About NRV Check Valve

NRV Check Valve

- Construction - Single Plate $ Spring Loaded Disc Check valve

- Compliance to - API 6 D / API 598

- Body MOC - WCB / SS304 / SS316/SS316L/FEP/PFE LINED

- Seat MOC - PTFE / EPDM/FEP /PFA LINED

- DISC - WCB/ SS304/SS316/SS316L /FEP&PFA LINED

- RATING - PN 10/ PN 16 FOR WCV & PN 40 FOR DISC CHECK VALVE

- Rating - ASA150# /ASA300#

- End Connection - Wafer Type Mound Between ANSI b 16.5 / BS 10 Table / DIN

- Operation - self acting

- Size - 15NB to 200NB For DCV 40NB to 600NB for WCB

- Leakage Class - Class VI

Versatile Material Choices

The NRV Check Valve is available with discs made from SS316, SS304, CI, CS, and WCB, catering to a wide spectrum of industrial requirements. Its adaptability ensures compatibility with corrosive chemicals, water, oil, and acid, making it suitable for demanding environments and applications.

Manual Operation for Precision Control

Unlike electromagnetic valves, this model is manually operated, providing precise, hands-on control. The valve acts reliably under high-pressure conditions in situations where electrical components are unsuitable or unwanted, giving operators direct oversight over flow management.

FAQs of NRV Check Valve:

Q: How is the NRV Check Valve with Pin (452001) installed?

A: Installation of the NRV Check Valve requires proper alignment with the pipeline, securing the valve between flanges, and ensuring the flow direction matches the arrow marked on the valve body. Manual tightening is recommended, considering the high-pressure capabilities.Q: What materials are available for the disc components of this valve?

A: Disc options for the NRV Check Valve include SS316, SS304, Cast Iron (CI), Carbon Steel (CS), and WCB, allowing selection based on the chemical and physical requirements of the application.Q: When is this check valve ideally used?

A: The valve is best used in industrial settings like water treatment, chemical processing plants, and oil distribution, especially where high pressure and compatibility with different fluidswater, acid, oil, or chemicalsare necessary.Q: Where can the NRV Check Valve be applied in an industrial process?

A: It is suitable for use at points where backflow prevention is crucial, including pump discharge lines in water, oil, or chemical systems, or anywhere that maintains directional flow for process integrity.Q: What advantages does manual operation of this valve offer?

A: Manual operation eliminates dependency on electrical power, ensuring continued functionality in environments where electromagnetic interference or power outages may occur, and providing responsive, direct control.Q: How does the structure of this valve accommodate high-pressure systems?

A: Designed with a robust check valve structure and high-quality materials, it reliably withstands the rigors of high-pressure fluids, reducing risk of leakage and enhancing operational longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Automation Valve Category

Jacketed Ball Valve

Price 4500.0 INR / Number

Minimum Order Quantity : 100 Units

Structure : Ball

Sealing : non

Pneumatic Actuator Ball Valve

Price 1500 - 200000 INR / Number

Minimum Order Quantity : 100

Pressure : High Pressure

Power : Manual

Structure : Ball

Sealing : non

Y Type Flush Bottom Valves

Price 1500 - 200000 INR / Number

Minimum Order Quantity : 100

Pressure : High Pressure

Power : Manual

Structure : Ball

Sealing : non

Manual Pneumatic Actuated Knife Edge Valve

Price 1500 - 200000 INR / Number

Minimum Order Quantity : 100

Pressure : High Pressure

Power : Manual

Structure : Gate

Sealing : non

LINEX FLOWSENSE LTE

GST : 23AAJHV2265D1Z9

GST : 23AAJHV2265D1Z9

B No. 106, Sheeba Complex, Near Regal Cinema, Indore - 452001, Madhya Pradesh, India

Phone :08071792078

|

|

LINEX FLOWSENSE LTE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry